Construction Cost Estimation: Key Ideas, Types, and Practical Aspects

Construction cost estimation has never felt like a theoretical exercise for me.

On every job I’ve seen, the accuracy of the estimate shaped everything that came after, from how confidently we built the budget to how smoothly procurement and scheduling held together. If the numbers aren’t solid at the start, the rest of the workflow becomes reactive, and it gets harder to bring a project back to where it needs to be.

This is why I take the estimating process seriously and break it down into clear steps. In the sections ahead, I’ll walk through how I approach cost estimation and how each stage fits into budgeting, scheduling, and procurement, so the project starts with the right level of control.

Table of Contents

- What Is Construction Cost Estimation?

- Why Accurate Estimating Matters

- Estimate Accuracy Evolves Across the Project Lifecycle

- When Should Builders Estimate the Construction Costs of the Project?

- Estimation Integrates with Budgeting, Scheduling, and Procurement

- 5 Main Types of Construction Cost Estimates

- Key Components Going into a Construction Cost Estimation

What Is Construction Cost Estimation?

Construction cost estimation suggests calculating the total expected cost of any project before work begins.

In practice, it means building a reliable and realistic financial picture based on the project scope, quantities, labor requirements, material pricing, and the schedule. It goes beyond the initial costs and considers possible problems and adjustments that may arise throughout the project’s life.

Typical cost estimation in construction organizes all project expenses into two groups.

Direct Costs

These are the expenses related to the physical construction work. Direct costs typically include:

- Labor costs

- Materials and equipment

- Subcontractor and vendor prices

- Quantities derived from drawings or takeoff data

Soft (Indirect) Costs

These support the project but are not tied to a single installation activity. Common soft costs include:

- Insurance and bonds

- Permits and fees

- Temporary utilities and mobilization

- Overhead, taxes, and interest

Together, these costs form the complete financial scope of the project. Depending on the owner’s requirements, the estimate may be delivered as a fully itemized breakdown or as a summarized total that reflects all expected obligations.

Why Accurate Estimating Matters

A complete estimate does more than reveal whether a project is feasible. It shapes the cost and schedule estimating process, allowing builders to:

- Validate the budget

- Plan procurement around real lead times

- Identify scope risks early

- Coordinate more predictably with owners and subcontractors

Accurately predicting any job’s cost will help ensure that it meets the budget set by owners and other stakeholders involved in the project. It also allows contractors to accurately assess their profits and losses beforehand, helping them decide if taking on a given job is worth the risk.

Practical cost estimation also helps to plan for contingencies and prevent any financial surprises that could derail the project. It allows for more accurate resource allocation and identifies areas that require extra attention or where costs may have been underestimated.

Estimate Accuracy Evolves Across the Project Lifecycle

The accuracy of any estimate depends on the stage of design, the quality of quantity data, and how well the team understands market conditions at the moment the estimate is prepared. Over the years, I’ve learned that estimating accuracy is not a single metric. It is something that improves step by step as drawings mature and real pricing becomes available.

Concept and Schematic Design: Broad Ranges and Early Assumptions

At the start of a project, the team often relies on conceptual quantities and benchmark unit costs, including the estimated cost of construction per sq ft.

At this point:

- Quantities are approximate.

- Scope is still shifting.

- Pricing reflects historical averages rather than vendor commitments.

Accuracy is naturally limited, but early estimates still help owners confirm feasibility and compare design options.

Design Development: Quantities Improve, Risks Narrow

Once the design reaches 30–60 percent, I start to work with more reliable takeoff data.

This is where the estimate becomes clearer because most systems and materials are selected. Structural and architectural drawings provide measurable quantities, plus preliminary subcontractor feedback becomes available.

Accuracy improves because assumptions turn into measurable scope items.

Construction Documents and Bid Phase: Market-Driven Accuracy

When drawings reach 90%-100%, the estimate becomes far more stable. This is the moment when:

- Subcontractors submit detailed pricing.

- Lead times influence procurement schedules.

- Labor availability and escalation rates can be evaluated realistically.

At this stage, the estimate reflects real market conditions rather than broad assumptions.

Accuracy is never absolute because even with perfect drawings, construction remains sensitive to price fluctuations, supply chain delays, and weather impacts. A strong estimate doesn’t predict every variable, but it incorporates enough allowance and risk adjustments to keep the project within a manageable range. When done well, it becomes a reliable guide for contracting, procurement, and schedule planning.

When Should Builders Estimate the Construction Costs of the Project?

The sooner, the better.

Contractors should ideally begin estimating the costs of any job as soon as they have enough information. Once contractors know the size, scope, and timeline of the project, they should get to work on calculating an accurate cost estimation as soon as possible. This will give them time to adjust their plans if needed and ensure they can remain within the agreed-upon budget.

The estimation stage should not come after the contract has started. Instead, it should be done before the project is awarded to ensure that all parties involved understand the costs and budget associated with the job.

No property owner will enter into a contract where they are unsure if their budget is realistic, and no contractor will want to be stuck with a project with costs beyond what the owner can afford.

Most construction proposals require cost estimation, as the contractor cannot provide a realistic bid price without them.

Estimation Integrates with Budgeting, Scheduling, and Procurement

Once the estimate is complete, it becomes more than a standalone document. A well-structured estimate is what shapes the entire project-controls workflow. It guides how I build the budget, plan procurement, structure the schedule, and evaluate subcontractor pricing long before work begins. When the estimate is reliable, every decision that follows rests on a firmer foundation.

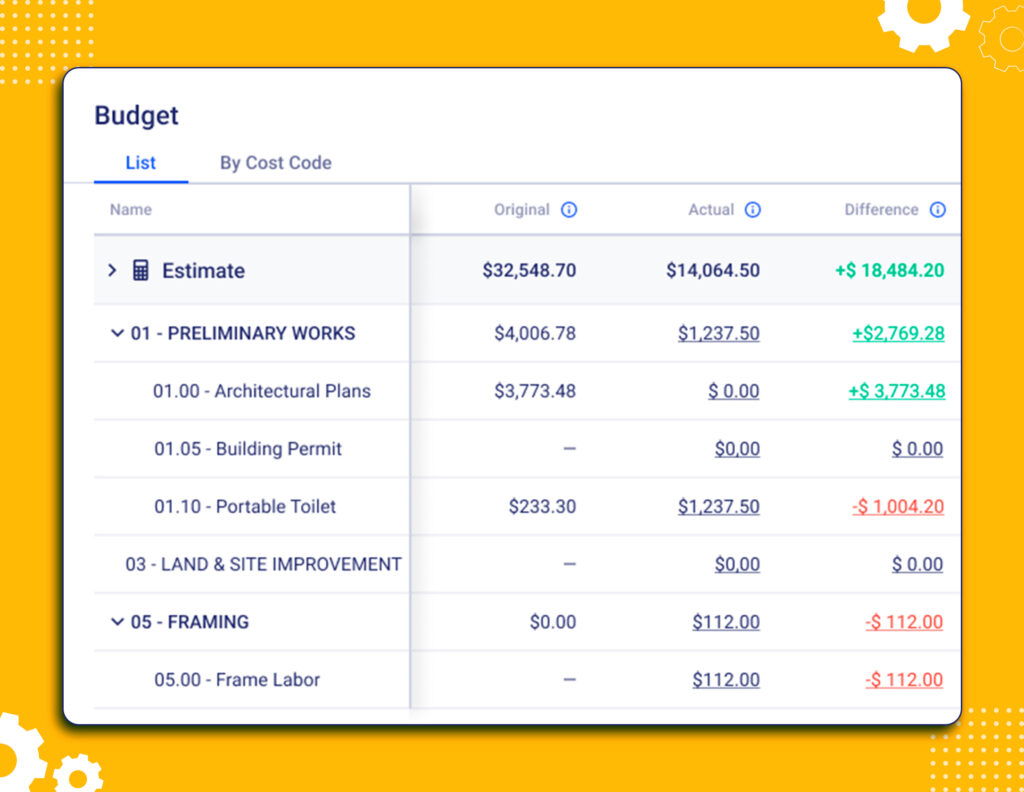

Turning the Estimate Into a Working Budget

The estimate is the first reference point for budget development. Because the quantities and unit costs are already defined, you can translate them directly into cost codes and set realistic spending limits for each division. This also helps you outline early cash-flow expectations. A budget built this way reflects the actual scope, which makes it easier to track overruns, forecast adjustments, and communicate a clear financial picture to the owner.

Using the Estimate to Plan Procurement

Procurement planning relies heavily on the clarity the estimate provides. Material quantities, expected labor, and the scope of each trade give you enough information to identify long-lead items, determine what needs early release, and decide where you need competitive vendor pricing.

By the time procurement schedules take shape, the estimate has already defined the sequence of what needs to be purchased, when pricing should be compared, and where the project may benefit from alternatives.

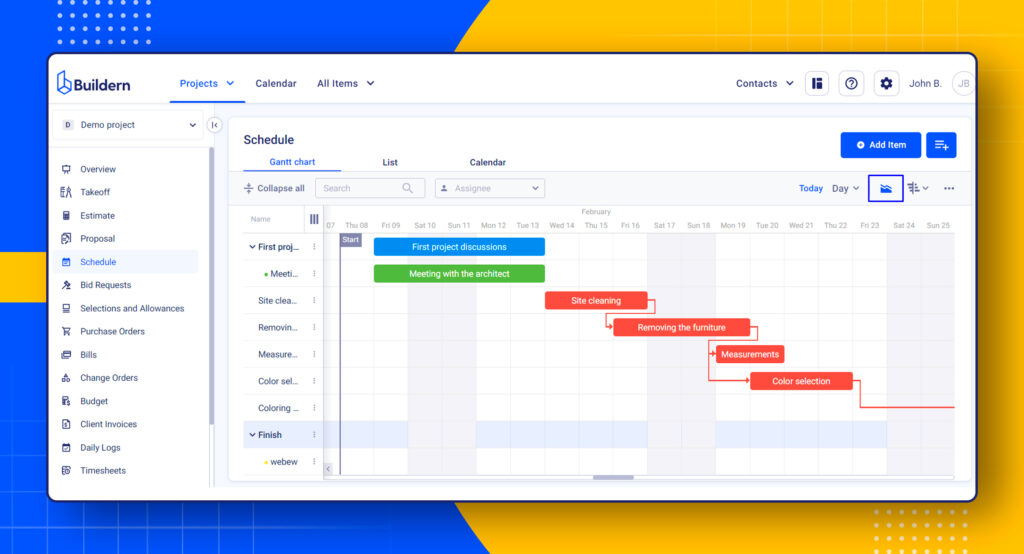

Linking Costs to the Schedule

The cost and schedule estimating process is always intertwined. When I prepare the estimate, I’m already considering installation durations, labor availability, and how each trade fits into the overall sequence.

This helps me understand when major cost centers will occur, where labor peaks may create pressure, and which scopes carry the risk of delaying others. The schedule becomes far more realistic once it is anchored to real quantities rather than generic task durations.

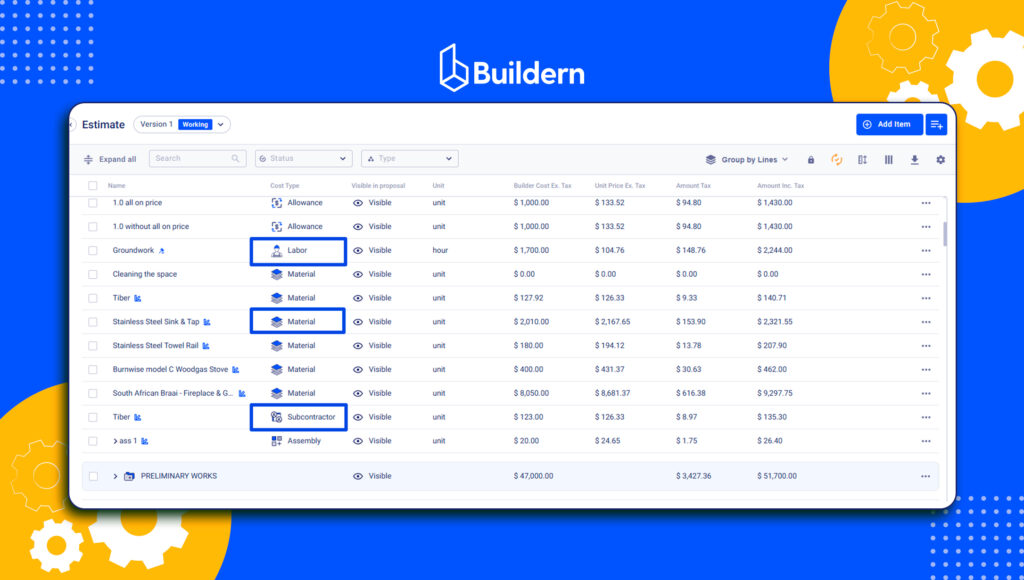

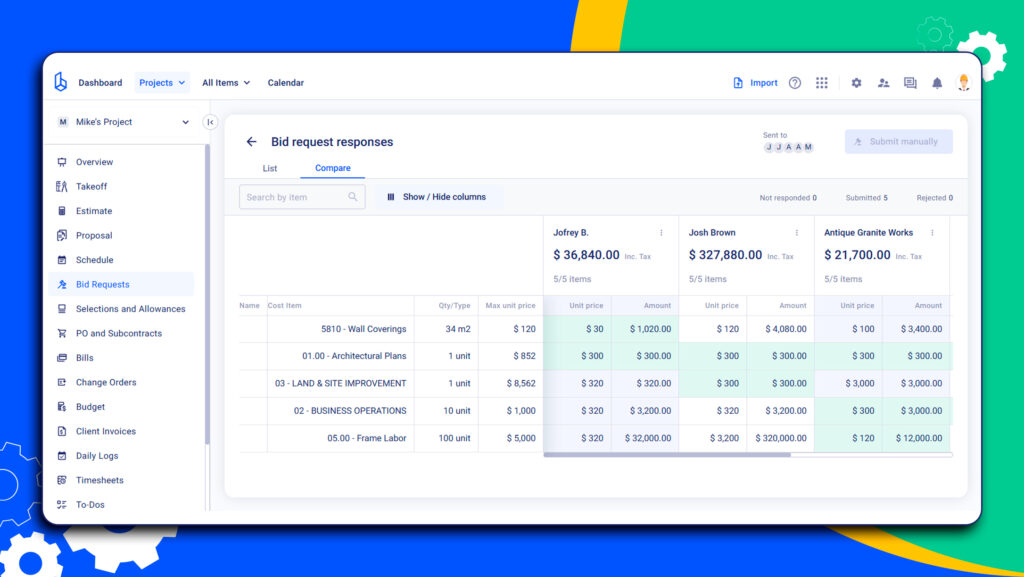

Strengthening Subcontractor Bid Comparisons

A detailed estimate also makes subcontractor bid evaluations more consistent. When quantities are already defined, you can compare incoming bids against the real scope rather than accepting whatever numbers subcontractors provide.

This makes it easier to spot where labor or materials may be undercarried, where exclusions could create downstream risks, and where clarifications need to be addressed before awarding the work. It reduces negotiation friction and leads to cleaner contract packages.

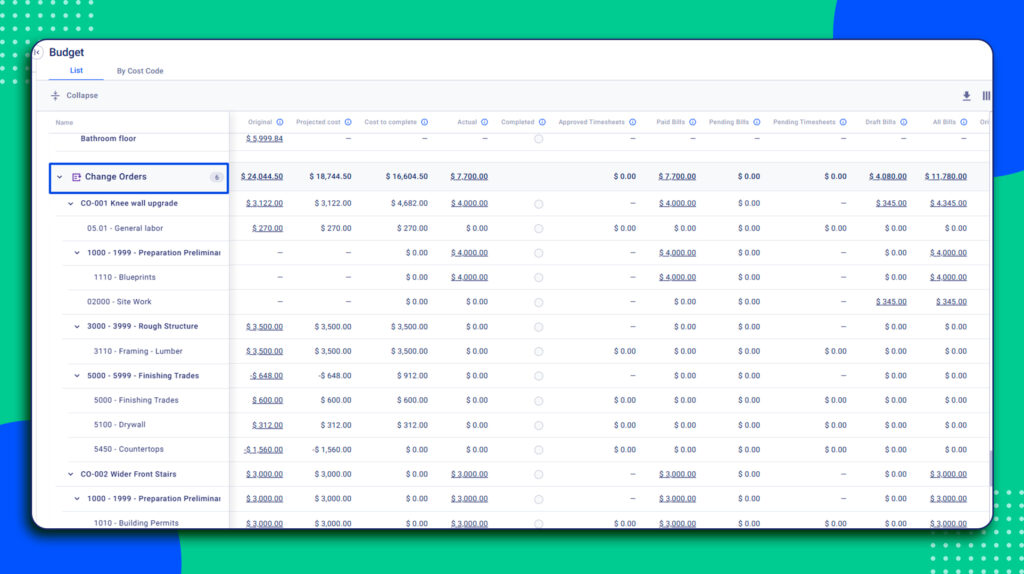

Supporting Change Order Management

Change orders are unavoidable in construction, but a strong estimate makes them easier to evaluate. When the original numbers are based on accurate quantities and clear definitions of scope, any adjustment can be compared directly against established pricing.

This helps distinguish genuine scope growth from pricing inconsistencies and keeps the budget aligned with the work performed. It also creates a clearer trail of documentation, which benefits both the builder and the owner.

5 Main Types of Construction Cost Estimates

There are 5 main types of cost estimations in construction, according to the American Society of Professional Estimators. These phases mainly differ in terms of the level of detail and accuracy, depending on the stage of the project and available data. The further the design progresses, the more specific the estimate becomes.

Here is a quick overview of each of the 5 main types of construction cost estimations.

1. Order of Magnitude Estimate – No Design Documents Yet

The Order of Magnitude Estimate is used when the project design is not yet available. It is an early-stage estimate that provides a rough overview of the cost of the project, and it can help contractors determine if a project should continue forward or be pushed back.

This type of estimate is usually based on contractor experience along with available information about the project. It takes into account the scope of work, expected materials and labor costs, as well as any other factors that could affect the cost of construction.

2. Schematic Design Estimate – Initial Layout Available

Once the schematic design is prepared, the picture becomes clearer. We now know the basic layout, room count, building form, and major structural decisions. With these elements in place, I can refine quantities and begin validating material assumptions.

A schematic estimate gives a more grounded sense of cost than an Order of Magnitude Estimate, though much of the scope is still flexible.

3. Design Development Estimate – Detailed Design Takes Shape

At the design development stage, most major decisions have been made, and material specifications start to solidify. This allows me to dig deeper into quantities and evaluate labor requirements with greater confidence.

Because this phase introduces detailed drawings and system-level information, the estimate becomes far more reliable. It also highlights any potential design-driven cost increases early enough for the team to respond.

4. Construction Document Estimate – Full Drawings Available

Once construction documents are complete, the estimate can be built on real measurements rather than assumptions. The drawings specify exact dimensions, material selections, and installation requirements.

At this stage, you can validate quantities, structure subcontractor outreach, and prepare an estimate that reflects the building as it will actually be built. This is often considered the near-final estimate because it is based on a mature, coordinated design.

5. Bid Estimate – Pricing Ready for Procurement

A Bid Estimate is created when the project is ready to go out for pricing. It consolidates everything from the earlier estimating stages and incorporates subcontractor quotes, updated material pricing, and procurement considerations.

This estimate becomes the basis for bid submissions and helps owners evaluate competing offers. For the builders I’ve worked with, it’s also the point where they align cost expectations with schedule formats and procurement plans to ensure the project can move into construction without surprises.

Before You Start the Estimate: A Bill of Quantities

Having a general understanding of the project cost is crucial before sending the proposal to the owner. That’s why contractors would normally create a bill of quantities – an itemized list of the materials and labor required for the job.

It provides a detailed overview of all the elements that will affect the project’s cost, such as construction material costs and labor expenses. It also allows contractors to make informed decisions about potential changes in order to reduce costs or increase profits.

BOQ creation (takeoff → squaring → abstracting → billing) is the mechanical foundation of cost estimation.

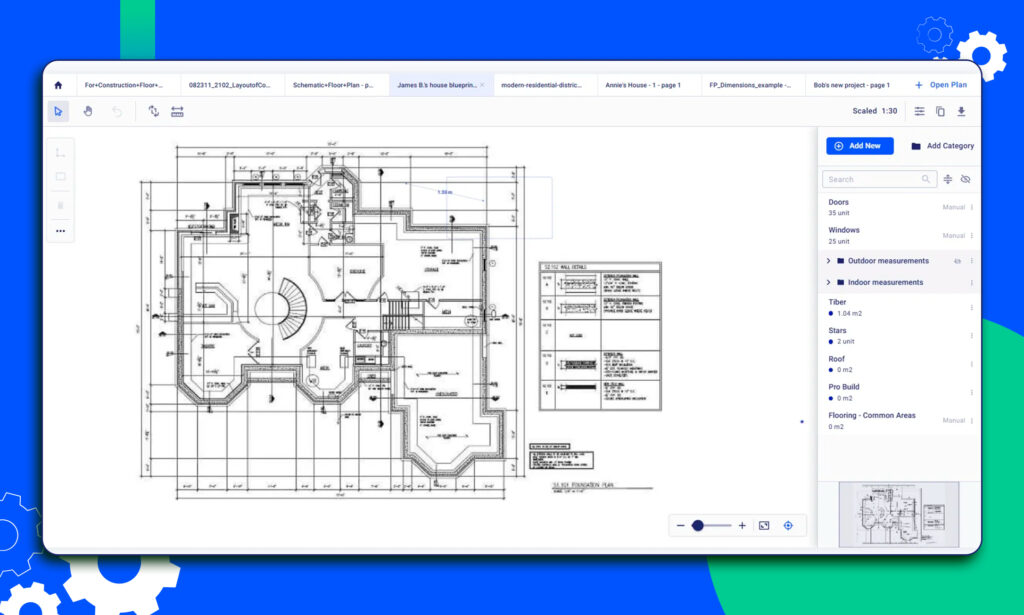

Takoff Quantities

The term takeoff in construction refers to the process of measuring the necessary materials required for a project based on the actual plans.

Once the drawings are available, contractors need to start the process of measuring and calculating all the necessary items. Different quantity surveyors use different scaling dimensions from drawings. Usually, contractors use area, volume, length, etc., to get the actual picture of the material items required for the job.

The outcome of this process is that the surveyor lists the material items and their quantities in detail.

Squaring

Once the initial takeoff is ready, it is time to start the squaring process – a step that provides accuracy and allows contractors to double-check their calculations.

The key thing here is to ensure that all the material items are not only quantified correctly but also match the dimensions of the blueprints. This way, you can make sure that no mistakes were made during the takeoff stage.

At the squaring stage, the surveyor multiplies the component’s dimensions by the square area of the property, then multiplies the result by the number of times the specific work happens during the project.

When this step is successfully completed, contractors get the total dimensions, length, volume, and area of the project and can proceed to the next step.

Abstracting

So, you have all the measurements and quantities in one place. Now it’s time to move on to abstracting – a process of grouping material items by similar types so that they can be easily identified during pricing and bidding.

The goal here is to create a set of standardized bills, which will help you avoid any confusion when preparing for the bidding process.

Abstracting requires a detailed approach; it includes combining similar tasks and components together. By merging them, surveyors can create a list of items that require similar pricing measures.

Billing

The final step of the process is billing. As simple as it may sound, billing is the process of presenting the results of the previous steps – surveyors present item descriptions and quantities in a structured format, which is called a bill of quantities.

A bill of quantities serves as a basis for a contract, and thus it needs to be detailed and precise. This is why it should include all the necessary information regarding the project’s scope of work – material descriptions, quantity breakdowns, labour costs, etc.

The goal here is to ensure that all the material items are properly priced and accounted for before submitting the bid. Contractors usually use itemized pricing, which also allows them to identify potential savings or areas where costs can be reduced.

Altogether, the above steps – takeoff, squaring, abstracting, and billing – prepare the base for an accurate construction estimation. It is a detailed document that helps contractors understand the project’s scope, cost, and labour requirements better – all while avoiding potential mistakes.

Key Components Going into a Construction Cost Estimation

Before we list the main construction estimate components, it’s worth noting that construction estimation for different projects can vary. This is why it’s important to adhere to the specific requirements of your project and include all the necessary elements in the estimate.

With that said, here are some of the most common components used during construction cost estimation.

Labour Costs (Hour and Rate)

Labor costs comprise around 50% of the construction project, so this element is crucial to the estimate. This number should include both the hourly rate and hours required for each employee, including skilled and unskilled workers.

To accurately assess required labor costs, estimators need to consider the complexity of each task and include separate entries for various employee types.

To clarify the estimate for your client, separate all the labour costs and associated elements, like overtime or bonuses. Give a clear picture of who will work on the jobsite, for how long, and at what cost.

Materials

Estimators already have an estimated cost of all the required materials from the takeoff process. This includes everything from construction equipment to raw materials and tools, which should be present in the bill of quantities.

If any additional items weren’t originally included in the list, estimators need to include them separately and adjust all the pricing accordingly.

A crucial tip here is to leave space for a potential increase in material costs, as prices can vary significantly during the project. Materials prices are often subject to fluctuations in the construction industry, where projects usually last for more than a year. Meanwhile, contractors can’t stockpile all the construction materials in advance, so the cost fluctuations don’t affect the project cost.

So, however challenging the prediction of material price fluctuations may be, estimators should always make sure to include this element in the construction cost estimate.

Equipment

The equipment section should include any costs associated with owning or leasing construction equipment, as well as costs of transporting and securing the equipment.

In some cases, it may be more rational to rent equipment instead of buying it. Depending on the size of your project, it can save a lot of money in the long run, which is why estimators need to include all the possible options when deciding on the type and cost of construction equipment.

Leasing equipment is usually a good choice when the construction site is far away from the company’s location, and transportation costs will outweigh the rental costs. It’s also a good choice if the project requires specialized equipment, which will not be used often for other projects of the contractor. In this case, as compared to buying it, renting will be much more cost-efficient.

Subcontractor Quotes

In some cases, estimators need to include subcontractor quotes. These should include all the necessary labor and material costs associated with the subcontractor’s project work. If you’re going to outsource a part of the project to another contractor or subcontractor, make sure to do thorough research and choose a reliable subcontractor that will cover specific parts of the project. Further, there should be clear agreements with the subcontractor regarding the timeline, payment, and quality of the work, as you will plan your construction contract based on the subcontractor’s estimate.

An important tip here is to ensure that you initially receive a quote from your subcontractor, which includes both labor and materials. This helps avoid any potential cost overrun later in the project.

In this regard, building a solid network of subcontractors you can trust and rely on is crucial. With a reliable network of subcontractors, this section of your construction estimation will be more predictable and easier to manage.

Indirect Costs

Construction is not only about materials and labor but also about the additional costs that go along with it. This includes anything from fees to taxes, insurance, and administrative fees.

Indirect costs can add up quickly, so estimators should take their time assessing them and ensuring all the expenses are appropriately listed in the construction estimating document.

If you miss indirect costs during the estimation process, it can lead to significant budget overruns later in the project. This is why you need to keep track of all the additional expenses and ensure they are properly accounted for.

Escalation

Escalation in construction is the increase in cost due to inflation, currency fluctuations, or other market factors. It’s important to account for this element in your construction estimation document as it can significantly impact the final project budget.

An escalation component in your contract secures you from budget overruns, implying that if prices rise, the project cost will still be covered, and contract terms will be adjusted.

Capital Costs

Capital costs are investments made in the early stages of a construction project and are planned to benefit the project for more than one financial year. Depending on the contract, some of these costs may need to be included in the initial construction estimation.

For example, capital costs can include purchasing a new crane or investing in a property that will later be used as part of the project.

Bonds

Construction bonds are insurance policies that guarantee the fulfillment of contract terms and secure both parties from financial losses if the project doesn’t run according to the predetermined schedule. Depending on the scope and size of the project, it’s important to include bonds in your construction estimation document.

The bond amount may depend on various factors such as the type of contract, duration of the project or even weather conditions at some point in its implementation.

Operations

Construction operations include the key activities happening on the construction site. Examples are measurements, cuttings, welding, post-construction cleaning, and other activities. All these need to be accounted for in the construction estimation document so that it’s clear what needs to be done and how much it costs.

By including detailed information about operations in the estimation document, you can ensure that all the required activities are accounted for and that there won’t be any surprises later in the project.

Variances

Variance in construction is the difference between a project’s estimated cost and its actual cost. Though the variance can’t be predicted with 100% accuracy, estimators should build some extra margin into their estimates to account for it.

This will help reduce the impact of potential cost overrun and ensure that the project is completed on time and within budget.

Contingencies

Contingencies and allowances built into the construction estimation document to account for unforeseen expenses during the construction. In other words, it’s an extra budget that can be used in case something unexpected happens, and you need to buy additional materials, hire more people, or incur other unplanned expenses.

An industry standard for risk contingency is 1-3% of the project’s hard costs. However, depending on the mutual agreement with the owner, you can also adjust the contingency amount, including some percentage of soft costs as well.

A contingency reserve can also pay contractors extra incentives or bonuses if the project is completed on time and within budget.

Final Observations

Cost estimation has always been the first real test of how well a project will run. When the workflow is structured, each phase adds clarity, and by the time you reach the final estimate, you already understand the budget limits, procurement needs, schedule pressure points, and the risks that could influence the outcome.

The more disciplined the estimate, the fewer surprises appear once construction begins. Quantities line up with drawings, bids are easier to evaluate, long-lead items are ordered on time, and change orders become manageable instead of disruptive.

Approach estimating the right way to have it as the roadmap guiding every major